Behind The Built Environment

Behind The Built Environment, a podcast from BESA where we delve into the latest industry news in the building engineering services sector. Join us for insightful discussions and exclusive interviews with leading industry experts, as we explore the trends and innovations shaping the future of the built environment and what impact they will have on you and your business.

Perfect for your commute, coffee break or toolkit downtime, these bite-sized episodes still pack a punch – giving you fresh perspectives on safety, skills, sustainability and the systems we all rely on.

Latest Episode: Why Most Modular Construction Firms Fail and How Reds10 Is Beating the System

In this episode of Behind the Built Environment, BESA Chief Executive David Frise is joined by Paul Ruddick, Chair of Reds10, about why industrialised construction must move from ambition to execution if the sector is to thrive.

Paul reflects on Reds10’s journey from a bedroom start-up to a £200m, debt-free business and explains why many modular firms fail by scaling too fast without fixing process, design and culture. He shares his perspective on fragmentation in construction, the role of digital tools and AI, and why vertically integrated models are key to improving productivity and quality.

From government procurement and planning delays to standardisation, diversification and decarbonisation, this episode offers a candid, experience-led view on what it will take for offsite construction and the wider industry to deliver sustainable growth and real transformation.

Meet Your Host, BESA Chief Executive, David Frise

Your host of Behind the Built Environment is our very own Chief Executive, David Frise.

David has been leading BESA for the past seven years, bringing over three decades of hands-on experience as a contractor in the built environment. Before joining BESA, he built his career in the family contracting business, where he gained a deep understanding of the challenges and opportunities facing our industry.

David started his career serving as a submariner in the Royal Navy where he developed the discipline, resilience, and problem-solving skills that continue to shape his leadership today.

With his unique mix of technical know-how, business insight, and strategic vision, David is the perfect guide to take listeners behind the built environment and into the issues that matter most to our sector.

What the Behind the Built Environment Podcast Covers

Behind The Built Environment podcast from BESA focuses on the key issues, trends and innovations shaping the building engineering services sector.

It offers in-depth conversations and interviews with industry leaders on topics such as procurement reform, product safety and standards, diversity and inclusion, regulatory change in the wake of Grenfell, business culture shifts, and how companies can respond to evolving legislation and industry expectations.

This podcast is perfect for professionals in design, installation, maintenance, manufacturing, and construction, and anyone whose business is affected by safety, regulation, sustainability, and best practice in the built environment.

Episodes We Think You’ll Like

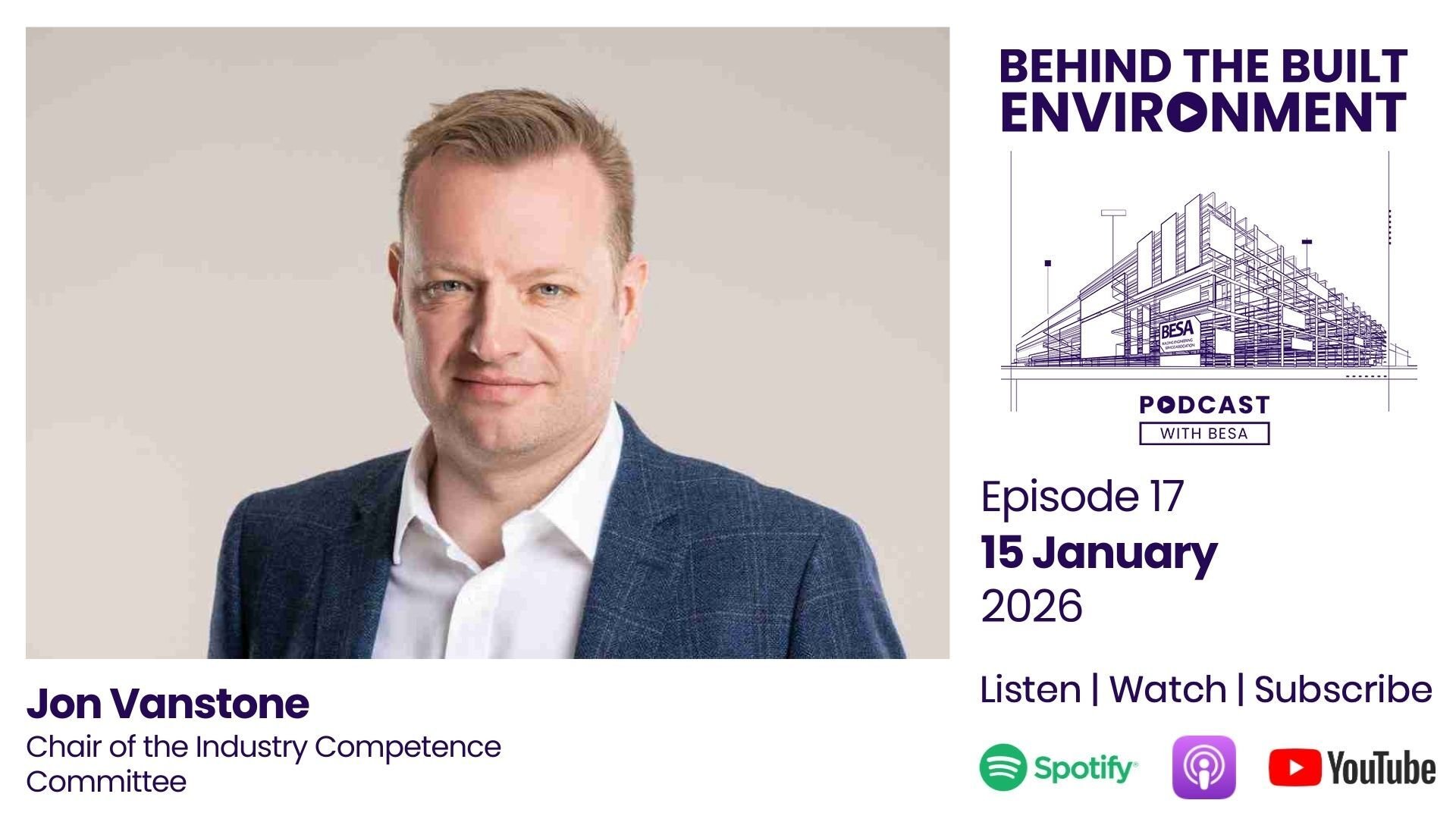

We’ve handpicked a selection of standout episodes that dive into some of the most pressing issues in the built environment. From building safety, innovation, and the future of engineering services, these episodes highlight the conversations shaping our industry today. Whether you’re looking for expert insights, practical takeaways, or thought-provoking discussions, these are a great place to begin your Behind the Built Environment journey.

BESA Podcast Extra

Behind the Built Environment Extra keep the conversation going, offering a shorter, sharper listen that brings you even closer to the people, stories and ideas shaping the building engineering services sector.

Whether it’s a deeper dive into a hot topic, reflections from our main guests, or a spotlight on emerging voices in the indutry, Behind the Built Environment Extra offers another layer of insight into the world behind our buildings.

Find all episodes, watch, listen and subscribe

You can explore all episodes of Behind the Built Environment right here. Watch the conversations in full, listen on the go through your favourite podcast platform, and subscribe to stay up to date with the latest insights shaping our industry.

Whether you want to catch up on past discussions or tune in to the newest releases, it’s all in one place, making it easy to keep connected with the people and ideas driving change across the built environment.

Sign up to our email list to stay up to date with the Behind the Built Environment Podcast

Episode Transcripts

David: Hello, I'm David Frise, Chief Executive of BESA, and welcome to our new podcast, Behind the Built Environment. The podcast where we will delve into the industry's latest news in the building engineering services sector. With leading industry experts, we'll explore the trends and innovation shaping the future of the built environment and the impact they will have on you and your business. Today, I'm delighted to welcome our first-ever guest, Lorna Stimpson, Chief Executive at LABC.

Lorna: Thank you.

David: Lorna's career in public service building control spans over 30 years in roles from building control surveyor up to senior managerial positions. Lorna joined LABC in 2008 as Business Development Director, advancing to Deputy Managing Director in 2015, and Chief Executive in 2019. Lorna has a proven track record in delivering complex projects and strategic reform. She works with DLUHC, HSE, the National Fire Chiefs Council, and Local Government Association as a member of the Joint Regulators Group, defining, piloting, and testing the new regulatory approaches.

She sits on the Industry Competence Committee and the Fire Protection Board. Lorna is a Board Director of LABC, the Construction Industry Council, and the Building Safety Competence Foundation. It's a wonder you've got time to come and see us today, to be honest, with all of that on a busy life.

Lorna: It's a busy time. Busy time for the construction industry generally. Yes, and I think we're all feeling the same at the moment.

David: How did you come into the industry? What was your entry point into this?

Lorna: I became a trainee building control surveyor at 16 and I've never looked back. It's the best career choice. We've just been taking on trainee building control surveyors, and I can honestly say to them that I wouldn't change a thing about my career. The 30 years in building control surveying, probably not quite 30 years, but in building control surveying was just fantastic. Fantastic. I would do it all again.

David: That's good. If you get so senior in your career and you do it all again, then you must have made the right choice.

Lorna: Yes.

David: We'd like to start off all these podcasts with a quick-fire question. Yes or no, if possible to this.

Lorna: Okay, I'll try.

David: Building Safety Act is clearly the dominant thing for you over the recent the last few years. Quite a few of these will be around Building Safety Act. Is the Building Safety Act the most important change in construction in your career?

Lorna: Absolutely. That wasn't yes, was it? I'm sorry. Yes.

David: Even more affirmatively, yes. Does it cover all buildings?

Lorna: Yes.

David: Is everyone in construction impacted?

Lorna: Yes.

David: Will the Building Safety Act result in behavioural change in the industry?

Lorna: It should. Yes.

David: Will the industry be better because of it in five years?

Lorna: Yes.

David: Do good companies, those who are competent and compliant, have anything to fear from the change?

Lorna: No.

David: Great. Thank you. All yes and nos. That was good. An absolutely. That's a huge boost. Could you just start off by just describing what you understand the Building Safety Act is about and why it's so important for the industry?

Lorna: That's a difficult question. Why is it so important and what is it about? It's about putting right the wrongs that we've had for so many years in construction, I think. It is fundamentally about cultural change. I know that is seen as quite a fluffy thing. It's not. It's not something that you can pin down, but it is about people doing the right thing for the right reasons, and consciously doing that. It's about competence. It's about culture. It's about putting safety before profit and a legislative process and framework by which that is the driving force. I truly believe that the Building Safety Act, if implemented appropriately, will do all of those things.

David: To make the building process safer, more certain, would you say, over that period of time?

Lorna: Yes.

David: To drive, we talked earlier, or you answered yes, to behavioural change. It's not just process. It's not a tickbox exercise. It requires people to change the way they operate and view the operations.

Lorna: Without a doubt. I'm obviously heavily involved in building control, and we are at the sharp end of that. Building control is becoming a regulated profession or has become a regulated profession. We're leading that change. I think the work that I do on the Industry Competence Committee as well is about driving cultural change across the whole industry. That's about attitudes. That's about people understanding what the legislation is trying to achieve, and the fact that that legislation is trying to drive safer buildings.

David: I guess with all change of that nature, you get we always divide them into threes. You get 33% immediately get it and change. 33% wait for something to happen and then change. You get 33% who never change. Where do you see us on that spectrum at the moment? I see quite a lot of the top third really going for it. Are we really getting into that second segment yet?

Lorna: In building control, we certainly are because we've had a deadline and we've had to work to it. In terms of construction, I think it will take a long time and a long time to filter down. The driver for this change was Grenfell, the Grenfell tragedy. That was what? Seven years ago now. Dare I say it, the impact fades from people's memories. If it's not something that's in your mind all of the time. It is obviously in ours because I'm working closely with the building safety regulator and DLUHC as part of this programme. We live and breathe it every day. Other people can be forgiven for not having been touched by the implementation yet.

I think the whole idea is that, gradually, over the years, this new way of working, the cultural change that we've talked about, the behaviours will start to trickle down throughout the industry. Construction is an unusual industry, and I think it will take some time. It's also a massive spanned industry, isn't it? I think we were talking earlier and you said something about from the shard to the shed. That is construction, isn't it? That is the massive breadth of construction. How long is it going to take for these new behaviours to come down to those people working on the shed?

It's going to take a long number of years, but it will happen. I'm very sure it will happen, whether it will be in my lifetime or career. I don't know, but it will happen. Or [crosstalk] determined.

David: I guess my career will end roughly the same time as yours. I would really like to have seen something happen by then. I was at an event last night at the Tower of London from the mechanical contractors, Vonterio. They held their conference in London, and their president said that they counted the number of cranes in London alone. It was over 100. They were staggered by the amount of work going on. Are you concerned about the resources available to planning and building control departments to actually deliver that, so they're not delaying the whole process?

Lorna: I don't think there will be any further delay than there ever would have been. capacity and local authority building control. Will we ever have enough people? I don't know how many is enough. I don't know, but certainly not impacting on delays to construction. The registration of building control professionals has now gone through that process, and we continue to work towards full implementation. What we're also doing within LABC, with massive support from English and Welsh governments, is to bring new recruits into building control. We know that we were an ageing profession. We know that there was a lot of people in the latter end of their career at this moment in time in building control.

We've been very, very conscious to bring in as many new starters and trainees into building control as we possibly can. We've done that over the last 12 months. We've taken on about 130 building control surveyors, and we continue to do that with government funding. Whilst we're losing people at the top end of their careers to retirement, as we would naturally, we're bringing people in at the bottom end to replace them, and to backfill those more experienced people that we're losing. It's all about the training. It's all about competence and building that professional network again, which is something that's very much part of our strategic direction.

David: The press will always focus on negative stories because that's what people want to read, by and large, you don't need to hear the good news stories. How useful is the three-month delay announced by government to building control officers complete that registration process. I'm assuming you agree with that decision to delay?

Lorna: I wrote to the building safety regulator and Welsh Government to request not a delay but an extension and that's what we've been given an extension to the deadline. Just to allow people to go through the process. I think what perhaps industry don't generally understand is it isn't just a registration process. Building control surveyors have got to prove their competence as part of that registration so through an independent company organisation. LABC's organisation that we set up some time ago the Building Safety Competence Foundation is gaining UCAS accreditation in 17-024 to be able to assess the competence of building control surveyors.

The surveyors have got to go through that really rigorous process to get their proof of competence before they're able to register. It's not a simple registration process and that three-month extension to the deadline that the BSR Welsh Government gave six months extension to the deadline. Very much welcomed by the industry and by LABC because it has given us that opportunity to get more professionals through this process. The building control professionals, they're willing they are ready and able, and going through that programme as we speak.

I think come July and in October for Wales, we will have the vast majority of current building control professionals registered in the system and practicing as registered building inspectors.

David: We represent mainly tier two contractors although they typically can now do more than half the work on a project but tier twos and below. They're very time-strapped there's I think still a lot of confusion in the industry about what's covered and how it's going to impact them. As a tier two contractor, what do you think they need to know and what should they prioritise in the way they operate in the future?

Lorna: I think it's fair to say that many people who aren't involved necessarily directly in HRBs so higher-risk buildings think that maybe the Building Safety Act doesn't impact on them. It does and the legislation has changed, and anybody who has an impact on a building whether it be a subcontractor the main contractor, they're what is now called duty holders. They have a duty to do their work in a certain way, and most of that is about competence and knowing their abilities. Whilst that might not necessarily have filtered down to your members yet, they are duty holders. That duty holder role doesn't just apply to HRBs the tall residential buildings it applies to every piece of construction.

Whether it be a kitchen extension or the shards, there are duty holders, and that duty holder isn't just the main contractor or the principal designer. The principal contractor principal designer it's everybody who has an impact on that building, or on that design. They are dutyholders, and they have responsibilities. Part of that responsibility is to understand their competence. Now, maybe at this moment in time, there isn't a requirement for them to prove that competence or be on a register. They are expected to understand their competence and their sphere of competence. The grey areas around what they are competent to work on what they have.

Competence, let's forget is about skills, knowledge, experience, and behaviours, and so it's not just about what you learnt in a book. Have you worked on that type of building before? Are there things that you don't quite understand, and it's your responsibility as a duty holder to understand where your skills, knowledge, experience, and behaviours lie.

David: Interestingly today, we've got a meeting in Rotherwick House which is where our offices are to discuss competence and the apprenticeship for ductwork. We've got 40 ductwork contractors coming in to do that. I guess the point I'm getting across here many of those competencies haven't really been fully defined yet. How long do you think the industry has to get that in place so that there's something to define competence against so someone who has a duty of care can understand what competence looks like?

Lorna: I think that many professional bodies, many organisations are already going down that route that you're starting to go down now. I think it's absolutely the perfect time for these disciplines, quite unique disciplines to start to understand what good looks like. I think what you're doing is what needs to happen, but that can only be done by the industries themselves. You can't tell building control what good looks like in building control if you're not from a building control profession. It's the same with your members.

It's for them to decide what good looks like and start to as you say develop the newcomers into that industry with that blueprint of what good looks like in a competent person in your industry. That can't be done to you that is for industry to do it themselves and that shows a mature industry.

David: Well, that's what we're trying to develop. We've operated competence assessment standard for 25 years, and it's only now just beginning to come into its own. That's because it's third-party accredited. Crucially also ask the question that many PQ processes done this, is that can you do the job? Which seems bizarre that we've never. We've asked, "Have they got insurance, have they got policies in place?" The question about, "Are you actually competent to do the job?" Never comes into question.

Lorna: No, and that's the difficult question, isn't it? That's where culture comes in, that's where behaviors and ethics comes in. Have you done this before? If you haven't can you find out how to do it? Are you competent to work on that scheme, so absolutely, your question is perfect. Can you do the job, not just do you want to do the job?

David: Is the price right?

Lorna: Is the price right, yes.

David: Many people have suggested that it's the end of value engineering as it currently exists, which is a euphemism for I need the price cut. Do you see that ending with the Building Safety Act really beginning to bite?

Lorna: I think it depends the extent that you're going to go with value engineering. If you're impacting on safety, then yes, it's the end of value engineering, but that should have never have been a thing. Value engineering shouldn't be to reduce something from compliance to non-compliance by using substandard materials or substandard labor that should not be a thing. It's about quality, isn't it? Value engineering no, I don't see personally, there's no reason why you can't do things just as safely or compliant or as compliant, but maybe a little bit cheaper, but not when you're compromising safety and standards. Absolutely not.

David: Many people have also questions about when it will really start. I think I use the term when will it really bite, and many people are suggesting that we need some prosecutions, and then people will go. Now we'll take some notice. How long do you think we are away from-- The industry fully understanding the consequences of the Building Safety Act.

Lorna: I think as you say until people start to be prosecuted, people don't sit up and notice. I don't think the HSE who obviously the building safety regulator is formed within the HSE. I think we all know that they don't stand off from prosecuting when they need to. If it needs to happen they will serve their notices.

David: Pre-Grenfell, I guess I'm pre the Building Safety Act. There was always I felt the perception in the industry that if building control didn't spot something or Clarkworks, for example, then we've got away with it. Actually, the building I live in that was the response of the developer that well, building control signed it off. There was always the perception that building control was somehow fully responsible for things and not able to do things properly. How is the industry responded to that?

Lorna: That was absolutely the perception before. It was never a fact. It was always the responsibility of the person carrying out the work to comply with the legislation. Building Control are there to secure compliance, if they see non-compliance, to do something about that. Things haven't changed, but now what has changed across the industry is that there will be an expectation for that principal contractor to say that they have complied with the legislation. That is their application for completion. Entirely changed, turned on its head.

The perception was wrong before, but what the legislation has done is made it clearer that it is the duty holder's responsibility to comply. Just because Building Control didn't happen to pop onto site when they were doing something inappropriate doesn't mean to say that they could continue to do something inappropriate. Again, it comes back to culture and behaviours. Why is that okay? Just one, we've been interviewing recently, and I have said this before, but we were interviewing recently for trainee Building Control surveyor. One of the questions was about integrity. What does integrity mean? Obviously, that question is because for Building Control or anybody in our industry, you've got to have integrity.

One young person, their answer to me was integrity is doing the right thing even when no one's watching. That was absolutely perfect. I think if the whole of the construction industry used that or just kept that in the back of their mind, then we would have a safer construction industry, we would have a safer built environment. Integrity and ethics is the thing for me.

David: Would you advise our members to have evidence, a full bank of evidence of how they have complied with the package of work they've done at the time?

Lorna: This isn't meant to be something that is difficult or hard to do or an imposition. This is just proving that you've done what you should do. In the same way, with Building Control surveyors now having to prove competence and register with the regulator, that's not about doing something different than they've done before. Dame Judith, in her report, was really clear. She wanted proven, measured competence, not just I say, "I'm competent or I passed an exam 30 years ago and therefore," this is not anymore. The construction industry is not, pass an exam once, practice for life.

I think that that's got to be the same for every part of our industry. You've got to keep up to date. We know that construction products alone change so often. It's such a massively innovative, area that how can you stand still? That constantly keeping yourself up-to-date is part of being a built environment professional and so very important.

David: Lorna, just to summarise what we've heard today to make sure that I've fully grasped this. The Building Safety Act is the key legislative change over the last few years. It affects the whole industry. I think we said the shard to a shed, everything and everybody. It requires cultural change, ethical behaviours on a scale that we haven't seen before and people need to do the right thing. I think we say even when people aren't watching you, it's for the industry to decide competence, what competence is, and indeed, I guess, what compliance is from that.

That tier two contractors or our members should always evidence their compliance, have a record of it for the future. It's your responsibility to provide that evidence. Nobody else is going to do it for you. Certainly, not building control.

Lorna: No.

David: I think we've reached the end of our time. I've got one final question and that is really, do you leave or are you currently optimistic or pessimistic about the future of the industry?

Lorna: Optimistic, but that's because it's Thursday. If it was Monday, maybe not. No, I'm definitely optimistic because I can only see good things. It's been difficult. There have been some hard decisions. There will be hard times coming for the whole industry. We've got to be better as an industry. We've got to be better. I think that we will be.

David: Lorna Stimson, Chief Executive at LABC. Thank you very much for joining us this morning.

Lorna: Thank you

David: Now to industry news. This is the week that T. Clark were acquired by Regent Acquisitions for £90.56 million, taking them from a public company back into private ownership. Interesting comparison with the failure of MJ Lonsdale recently. There's still plenty of flux in the market and some consolidation, no doubt, to come. Having just interviewed Lorna Stimpson from LABC, it's interesting to note as well that the Grenfell inquiry has been further delayed, and we will see when that finally gets published, and the impact that has.

In BESA news, BESA are very proud to be the competition partner for refrigeration and air conditioning, along with Mitsubishi and Refcom. The national finals will be held in November, with the WorldSkills finals being held in Shanghai, China. BESA have also launched TR19 Air, along with complementary courses from our approved suppliers. That is an opportunity to evidence your competence and compliance, as we discussed earlier in the podcast. In Scotland, new build heat standards have been introduced, which came into force on the 1st of April.

Finally, I had a letter published in the Financial Times, which you've no doubt all read, about boiler pricing strategies and the consequences of government consistently changing policy at the last minute. A quick reminder that we operate, as BESA, the competence assessment standard, a three-part standard business management review, a technical audit, and organisational capability. Which is UCAS accredited, which is your opportunity to evidence to those duty care holders your competence and compliance. Crucially, we ask the question that many PQ processes don't, is can you do the job? On that note, thank you and goodbye.

David Frise: Hello, my name is David Frise, and this is Behind the Built Environment, the podcast from BESA, the podcast where I delve into major issues facing our industry through in-depth conversations with key industry leaders. Join us as we explore the trends, challenges, and innovations shaping the future of the built environment. Our guest today is Dr Jo Jolly from Ofwat. Welcome, Jo.

Jo Jolly: Hi, David. Thank you.

David: Jo joined Ofwat in August as their Director for Environment and Innovation. Prior to joining Ofwat, Jo was Head of Project Futures at the Infrastructure and Projects Authority in Cabinet Office. Leading the implementation of the Transforming Infrastructure Performance Program, and with over 20 years in project delivery, including the successful delivery of the Environment Agency's $2.6 billion Flood Risk Management Program, she understands firsthand the problems and opportunities we have in delivering better outcomes through all that we do.

She believes we urgently need to transform our approach in order to achieve the best outcomes for the economy, the environment and society as a whole. Jo is pioneering the use of data analytics in this transformation, including as a founder member of the Project Data Analytics Task Force. As I said, welcome, Jo. Thank you for joining us today. We always like to kick off with some quick-fire questions because it sets the agenda. You've got to try and do yes-no to these, okay?

Jo: Oh, that's quite hard for me. [laughs]

David: Quite hard for everybody. Number one, can better collaboration between water specialists and building engineers lead to improved water management for more efficient HVCA cooling and heating systems?

Jo: Yes, wholeheartedly.

David: Would integrating water-saving technologies in HVAC design improve both water and energy efficiency in building operations?

Jo: Yes.

David: Is regular communication between water specialists and building engineers essential for ensuring a reliable water supply for all uses, including emergency uses such as fire suppressants?

Jo: Hugely, yes.

David: Is there a role for innovation in data analytics and novel technologies to enhance HVAC system performance?

Jo: Yes, I'd love to explore it. [chuckles]

David: Great, we will. Would co-developing maintenance protocols between water specialists and building engineers help to improve the effectiveness and efficiency of these water systems?

Jo: Yes.

David: A note to our editorial team here, we need some no answers in here, otherwise, it's too easy.

[laughter]

Jo: They're great ideas running through all of that, David, aren't they?

David: They are. They are great ideas, and let's explore them. First, it's always interesting to know how you ended up here today. How did you end up? Why did you choose this industry at whatever age you came into it? What started you off on the sort of engineering path?

Jo: Interesting. I don't think I've ever had a grand plan in mind. Growing up, I certainly cared massively about the environment, growing up in the '80s. I think it was very-- the awareness of climate change, the impacts of it was very much around me then. Actually, I didn't study engineering. I studied geophysics at university, and I went to Liverpool because I loved the Beatles. What better reason?

I suppose I've followed my nose, and you could say my heart, throughout my life and been incredibly fortunate to be able to do that. I think coming back to that, how fortunate we are and what we do with that is a theme I want to bring out during this discussion as well. I studied geophysics and then hydrogeology as an MSc and eventually a PhD, and then thought I ought to get a proper job and worked as a consultant in groundwater and contaminated land.

Then I joined the Environment Agency, and I sort of moved into project delivery and particularly delivering the flood risk capital programme. A lot of infrastructure, construction and design. I think just over my lifetime, I've become, in my working life so far, hopefully, a few more years to go, become increasingly clear about sort of what's my purpose. What's my purpose in leadership? What's my purpose in life?

I've got to an age where I don't really care if that sounds cheesy anymore because I think if you're really clear on your purpose, then that's your driving force. That's what gets you through your hardest days. That's what puts a spring in your step. It does for me. It became very clear to me that a life well lived for me, David, will be that I've done the best I can through the work I do for the planet before I die. That's it. It's pretty simple, pretty clear.

There's quite a lot in that, what is the best we can do? My yardstick for that is Sir David King. I had the absolute privilege to be invited to a close meeting with him two or three years ago now. He talked about not only, as we all know, must reduce greenhouse gas emissions dramatically and draw them out of the atmosphere at scale, it's not enough. Certain climatic systems that we depend on for life on this planet have gone beyond a tipping point.

One of the ones he talks about was the Arctic. He whatever we do with greenhouse gas emissions, whatever we do, more ice in the Arctic now melts in the summer than can ever refreeze in the winter due to the shrinking ice, reducing reflection of the heat, more absorption of the sun's heat by darker water. That's gone into a feedback loop. Whatever happens, we're set on that path. I'm afraid that's pretty catastrophic. We're locked into a very different climatic future right now.

What David King chose to do, nobody told him to do this, he has established the Centre for Climate Repair, because what he's saying is we need to repair damaged climatic systems. He's established a Centre for Climate Repair with engineers at Cambridge University, and they're developing technologies to refreeze the Arctic using marine cloud brightening technologies. That's my favourite project in the whole world, because if that doesn't succeed, like I say, we're not on a good path.

That's what doing your best looks like, David, to me. Obviously, on a daily basis, I'm failing miserably. It's good to strive, isn't it? It's really good to strive and to think, "Yes, well, what could I do? What could I do today? What's in my gift through the choices I make in this privileged, fortunate position I'm in? What's the best I can do?" That's why I'm here.

I feel extraordinarily fortunate to be in an organisation like Ofwat, well, specifically Ofwat, because the organisation you're in really decides to a large degree what and how much you can achieve. To be in an organisation that is kind, empowering, trusting, bold and full of humility about how we can do things better, I can't imagine a more nourishing and enabling and ambitious environment to be a part of. That's why I feel extraordinarily privileged to be here. I will promise to do my best.

David: That's a fantastic answer. From a fairly serendipitous, you went to Liverpool because of the Beatles, through to your purpose, which I think you've perfectly described. I think purpose is something that, particularly for the younger generations, is something that's really important. When we set out in BESA, that our purpose was actually a better industry, because you get a better built environment that has huge social benefit, and also helps mitigate the climate crisis to a degree. That has helped us attract some really good talent, younger talent, because they believe in the purpose. That's really encouraging to hear that. It's very encouraging to hear that within our regulators, we have people who genuinely care, and you can't hide that, as they say.

Jo: Could I just comment on that, David?

David: Yes, of course.

Jo: I absolutely agree that younger generations who are coming through absolutely have climate and nature and a purpose pretty much at the top of their agenda. I think the thing you and I, and others like us really have to recognise is our last best years for doing anything to mitigate the impacts of climate change is now, is the next year in front of us, and the next year in front of that.

We're the ones in position of influence, we're the ones in position of power. Whilst the younger generation do care deeply, it's us that have to do the action, because we're here now, together with our younger colleagues, of course. I think I often hear, "Oh, it's the younger generation coming through." I think, yes, but it's us, it's here now.

David: It's easier to give it to them to deal with, then we don't have to worry about it, isn't it?

Jo: Perhaps.

David: Yes. A few questions now. Off-way shifting to be an activist regulator, how do you see that working? How can this further enable effective relationships between regulators and the wide industry and the supply chain?

Jo: Yes, I love this term, activist regulator. The person who really brought the meaning and how we live activism to life is a lady called Carmel McConnell. Incredible lady. She spoke at the Association for Project Management conference a year or so ago. She established the Breakfast Club for children who didn't have the means to have breakfast. before they went to school, which is so fundamental for children.

She talks about activism as being less about talking, more about doing. She talks about it being underpinned by passion and purpose, but also a plan for how you implement it. There's this real sweet spot between the passion and doing. I think the other thing that she talks about is not to underestimate the value of small steps. Whilst a lot of the challenges ahead of us can feel enormous and possibly overwhelming, take small steps because they have an impact. She's demonstrated that through the work she does. She has a great book. I'm not on commission, but I would recommend reading it.

Yes, as a regulator, what can we do? There's progress well underway at Ofwat, including how we are developing our sector performance directorate. That's led by a fantastic lady called Helen Campbell. Really, that's understanding how we make better use of data, sharing data, being more transparent, and really understanding how our sector is performing and what we can do as regulators to support, enable and hold to account.

Again, there's that real sort of sweet spot as a regulator where we need to be enabling and holding to account fairly and equitably and transparently. The place I'm really exploring, though, in that activist space is, as well as what we regulate and the measures, hard measures that we set, and quite rightly, companies are held to account on, what are the choices we can make around how we deliver?

I think the best example I've got of this is the Boston Barrier Flood Risk Scheme. It was a project delivered by the Environment Agency a few years ago now. What the project team did was they retrospectively mapped the benefits of the project against the UN Sustainable Development Goals, the 17 goals.

This wasn't something they planned at the outset of the project, but they did look back afterwards and say, "Well, as well as it being a phenomenal engineering project, what other benefits did we deliver through this multimillion-pound scheme?" They recognised that, well, actually, half the design team were female, so that contributes to better gender equality.

BAM Nuttall, the constructors, they only employed people within a 50-mile radius of the project. In a relatively deprived part of the UK, that contributed to more sustainable communities and contributed to decent work. The project team went into schools to talk about engineering and climate change and flood risk management. Again, contributed to better education. Actually, when they went through the whole 17 goals in varying degrees, they actually contributed to every single goal.

What we recognised was, well, imagine if we start every project thinking through the lens of these goals. All those things were just choices. They weren't in the project mandate. They weren't in the contract. They didn't cost any more. They were choices people made because they could. Back to choices, back to Sir David King.

Over the next five years, the water sector is going to be investing more in infrastructure than we ever have since privatisation. How do we, through every pound that is spent, wring out the most value for society, for our customers and for the environment? I know, and we've demonstrated, there is so much more we can do, but it depends on collaboration. It depends on data sharing. It depends on having the will and the passion to do this.

If I can just finish with just last week, I was at a conference, the UK Summer Forum with British Water. They hosted an event for the supply chain, and water companies were there. It gave me so much heart and so much optimism that we can and will be able to achieve this because everybody in the room was advocating a similar mindset. I found it phenomenal. I think there's a coalition of people who want to make a big difference for the greater good because they know we need to. That's the activism I want to be tapping into in my role as Director of Environment and Innovation.

David: That makes great sense. I'm currently reminded by, in the week where ISG have collapsed, you talked about choices being made. Quite often, there's this cognitive dissonance between what people say they do and what they actually do. You have centred on the use of data. Do you use data to actually unearth the difference between what people say they do and what they actually do? Particularly in things like energy performance, we see that they claim they've made these savings, and actually, they haven't at all. How do you use data to unearth any of those discrepancies, shall we say?

Jo: Maybe not one to get into around ISG and the impact that has on people, homes, livelihoods, lives. It's absolutely devastating. I fundamentally believe that the whole system is set up to fail in terms of how we procure, how we contract, how we reward, how we incentivise, how we pay. I fundamentally believe the entire system needs to change. I think it's in our gift to do that.

How many things need to fail before we do that? That's not something in my gift or influence, sadly, but I know there are people, there's a lady called Louise Lado-Byrnes, who is leading a different approach. She procures purely on behaviours, purely on behavioural workshops, not about cost, not about scope, purely on behavioural. She gets a more diverse team innately, and their delivery performance outstrips the norm. The payment mechanism is different, the incentivisation mechanism is different, and what they value is different. They largely value behaviours.

How do we start to drive a different model, and again, what can we do? What can we do? Okay, maybe I can't change the whole system, where could we start to explore more of these things? Where could we start to try to do things differently? Again, that is something I'd love to explore. There's people doing it, but only in small pockets.

When you talk about how much can we believe what we're hearing, I think is a large degree what you're saying, isn't it? Sometimes what we're hearing doesn't seem to play out in reality. This is my huge interest and focus on psychological safety, David, because every single lessons learned report that's ever been published, what does it say? The reason a project went well is, why? It's not because we had a brilliant risk register or a fantastic forecast or a great Gantt chart. They are important. Absolutely, they're important.

Why did it go well though? When things went wrong, we had each other's backs. I could come up with great ideas and people listened to me, and we all pulled together. When projects fail, what's the main reason? It's people, it's behaviour. I spoke up, but nobody listened. I was too scared to speak up. The tragedy of the Challenger disaster. People knew those O-rings were going to fail. We look back on every single lessons learned. People in the team knew, but they weren't heard or it wasn't acted on.

One thing that we trialed at the Infrastructure and Projects Authority when I was there, and it's something, again, I'd love to explore more, is with the use of data and analytics, we can capture and start to quantify human behaviour. I don't mean in a sinister way. What we did was it was very simple app. It's called Meeting Quality. I have no shares in the company. I just don't know another product that does this.

Every week after the project team meeting on our transforming infrastructure performance delivery project, after the team meeting, the email would just plop into our email box. A very simple 60-second survey. How motivated are you feeling? How likely do you think this project is to succeed? Just a sliding scale. Are we measuring risks? Sliding scale, very quick. Then a bit of free text.

Ours was, if when you leave the room, you're asked by a trusted colleague, how's the project going? What would you say? You put a bit of free text. It's all anonymous, but everything is shared verbatim with the team. Everyone will see the comments, but you won't be assigned to names. Then the AI that runs across all that data starts to give real insights around how the team are feeling. Are they quite optimistic? Is the language positive? Is it fearful? Is it negative?

Also, what are the trends over time? Not on our project, but on another one, the team was staying very optimistic. Yes, we're going to deliver. The sustainability of their working practice, how they felt was dropping off. That's a lead indicator that a team is beginning to burn out and get tired. As a leader, you could step in and say, "What's going on? Let's talk about it. How can I help?"

Back to the sort of question about, how do we know what's really going on? This gives people a forum to be able to say, "I'm concerned about this," because we only really report on projects. I'm talking very much about projects, but you could substitute this for any performance measure. We only measure time, cost, and quality. The lag indicators, by the time you see anything in time, cost and quality, it probably happened many months ago. Unless you've got psychological safety in your team, which I would challenge most teams do not, then how can you trust that data? How do you know people aren't just telling you good news because they're too scared to tell you otherwise?

These insights, these behavioural insights start to give us lead indicators on how the team are feeling. Why not have that on your dashboard next to your time, cost and quality? Then you start to get so much more of a rich picture. I think, in that way, we start to-- again, it's small steps. It's activism. We start to shift the dial on everyone having an equal voice around that table, everyone being heard, and those good news cultures not being allowed to fester in all honesty.

David: We have a feeling that there's a toxic relationship with information, that if you're asked to provide some information, the first question you ask yourself is, how can that be used against me? It will be in the contract.

Jo: Fear, isn't it? Fear, psychological safety. Absolutely. How will this be used against me? Even when I was at the Infrastructure and Projects Authority, even sharing data between government departments, there was a fear. How would this be used? Is this going to be used as a stick to beat me with, someone said, just between departments.

David: We just had to abandon a project on quantifying defects in buildings, totally anonymized. People were very enthusiastic, but when it got to the commercial departments, it was stood on. People wouldn't give us totally anonymous information.

Jo: Here we are trying to improve health and safety. Here we are trying to tackle the greatest threat to our existence. We manage the wrong risks, David. We worry about the wrong risks. In doing that, we make the risks that really matter so much worse.

David: The human condition, I think. How can the water industry and building engineering sector work together to deliver higher-quality water management strategies to make buildings safer, healthier, and more sustainable? Are we currently missing opportunities to improve the built environment water services? I guess from your last answer, yes.

Jo: [laughs] I had the enormous privilege of coming along to the BESA conference last year. As I said, I've never met people like you all. You and Claire Curran stood up at the start and you talked about the nature and climate emergency. You talked about, we're going to do it, whether we're being told to or not. It was, again, that sort of choice, the doing the right things. It's the right thing to do and connecting people. By the time I got up to speak, I thought there's nothing more for me to say. [chuckles] These people are incredible.

What became so sort of shockingly obvious to me, and it had never even occurred to me, I think you're some of the most well-hidden heroes that there are, because like you said, everything that you and your members manage and deal with are at the heart of our biggest problems. Health, healthy buildings, the health issues that come from poor air quality, nature and climate emergency, so reducing carbon and the cost of living, obviously the cheaper, more effective we can make heating and air ventilation, the better.

You and your members have the ability and are unlocking so much potential and so much solving so many thorny issues that are at the heart of what our country is grappling with. I don't know what those connections are right now, but given that water, as the fabulous Ewan Rose said, is like the lifeblood of a building, then there must be connections. There must be ways to explore how we can work better together and how-- yes, what are the opportunities for us to be working better together? All of the potential that your members and your industry leave us is extraordinary. I'd love to explore how we can work more with you in the best way we can.

David: Yes. We like to describe ourselves as the industry you've never heard of but has a massive impact on your life.

Jo: That's it. Simply championing what you do, that's where I'm going to start, David, just championing what you do.

David: Most of it's hidden, and if you succeed, people aren't aware of it.

Jo: True.

David: When it goes wrong, that people are aware of it, as you know in the water industry, they take for granted clean potable water until they haven't got it. Then it's a disaster.

Jo: Yes, it's a fair analogy. When things are going well, maybe, you're doing well. Oh, sorry. When things are quiet, you're doing well.

David: That's the thing that makes it very difficult for people to value because it's a given. It's like breathing air, you just assume it's there until it isn't.

Jo: Yes. I remember chief executive of the Environment Agency for a good chunk of time while I was there was Sir James Bevan. He talked about wanting to make the Environment Agency better known and better loved. That was a phrase he had. He said, there isn't a town or a village in England, because that's what the Environment Agency covers now, where the air quality isn't better or the water quality isn't better or the ground quality or the waste, because the organisation sort of touches everything everywhere. Now, of course, we're all striving to do better. Of course, those standards need to be ever-improving. I'm not questioning that. Like you say, what we often don't know and don't realise what's going on when things are working well, that's for sure.

David: In your role, do you influence planning approaches, or can you influence planning approaches to ensure that built environment projects take water management issues into account at the design stage to avoid future problems?

Jo: At Ofwat, and this is an area that I'm getting more involved in, but it's very much early days for me at the moment, there is a collaboration between the Environment Agency, Ofwat and the Drinking Water Inspectorate around how we support and enable those early design stages of major infrastructure projects in the water sector. Yes, there's a huge role to play. I'd be interested to explore where BESA and some of the sort of building regulations and other aspects of water usage in planning and building, not that we have a regulatory role there, but it would be interesting to explore where we might be able to input, inspire, and enable more.

I think back to my earlier point, whilst that is very much focused on water usage, water quality, vitally important things, obviously, I also want to be saying, and what else? Let's be thinking about the UN Sustainable Development Goals. It is a framework that exists as a country. We are committed to delivering on it by 2030. Although curiously, we seem to have stopped reporting on it, which I don't understand why.

David: Sustainability in net zero. There's a big drive for growth at the moment. Where do you see sustainability in net zero sitting in the list of priorities? I think I know the answer to this, but if you could just tell us what you think.

Jo: If you'd asked me not that long ago, David, I'd have really worried about where it is sitting generally in the list of priorities, where it is in my list of priorities. Did you see David Lammy's speech last week? Our foreign secretary is saying our biggest threat is the nature and climate emergency. He's saying it's a bigger and more immediate and more urgent threat than Putin and terrorism. I'd encourage anyone to read the speech. It's on gov.uk. I think that's profound and correct.

When our foreign secretary is saying this is the biggest threat we face and this is what we as a government are going to be tackling, for me, that's a massive sea change. Whilst I really want to encourage everybody to do what they can, regardless of the limitations around this, I often hear people say, "Oh, well, we can't do that because it's not in the Treasury Green Book funding rules or it's not in the contract."

Just a few years ago, the Institution for Civil Engineers ran a survey about what makes good design. One of the questions was, what's the biggest blocker to including greenhouse gas emission reduction and climate adaptation in your designs? The main answer was, it's not part of the project brief. I just remember thinking, oh my God, when did this happen? When did this sort of learnt helplessness set in that we have to be told to do the right thing?

Let's wake up to what we can do. Let's really test the limits of what we can do within the rules, within the policies, within the funding, but make sure you're at the absolute limit, not down here somewhere, which is, I think, is often where we are. Of course, if you have leadership from the top, from our government saying this is our most important and biggest and most urgent threat and this is what we're going to be taking action on, that's massive. That is massive.

Also, within DEFRA, we have our first Minister for Nature, Mary Creagh, extraordinary leader, and the work that Steve Reed is doing to advocate for the environment and for nature. I think with the messages coming from the top it's very clear where it sits in the priorities. I was going to say encouragement, that's a bit light, what I want people to do is irrespective of whether you're hearing those messages from the top, please think about what you can do, what you can do every single day in the choices you make because your agency, your influence is always so much bigger than you realise.

David: How can building services firms get involved in Ofwat's Breakthrough Challenge and gain access to the funding available for collaborative innovations and projects, and what sort of innovations would you like to see from our sector?

Jo: Yes, so we have our Breakthrough Challenge, which runs on an annual cycle. For the Breakthrough Challenge, a water company has to be sort of the lead partner, but they can absolutely collaborate with people across all sorts of industries and sectors. I'd really encourage people to get involved. That runs on a cycle between September and April for putting submissions in and through to getting the funding. Now is a great time to be looking at it.

In terms of the innovations, it would be great to see, I'm not sure, and what I'd say to anyone interested is please get in touch with me and my team if people have got ideas that they'd love to talk through or some advice or anything about how to get more involved, then we'd be more than happy to help.

I suppose the one thing I'd say though about innovation is often we think about shiny things or gadgets, but I'm a big believer in just sort of doing the basics well, and that can be remarkably innovative and have a massive impact, positive impact on how we do things. For example, how we visualise data, how we share data, really driving up productivity, really enabling collaboration through data and technologies.

Sometimes it's the very simplest things or some of the broader enablers that drive the biggest benefits. I'd encourage people not necessarily to be thinking about shiny gadgets, which are great, too, but how can we fundamentally change the system for the benefit of all to deliver the best outcomes? Any ideas, nothing's too unusual or possibly even dull to talk about. I think sometimes the dull things, the things that seem a bit boring is where we need to focus our time and effort, [laughs] but I mean it. It's the grunt, and we don't want to do it.

David: That's all my questions, and our time is up, so I always like to try and summarise what we've discussed today, which is going to be a bit of a challenge today because we have been everywhere from Liverpool and the Beatles through to the Arctic Ocean. Just to summarise what I think we've said here is that it was your passion for the environment, sustainability, the climate disaster that drew you into the industry.

You want to make a difference through having a purpose that you think you can make a difference, and for people to do things, have agency over the things they can control and do them, and specifically don't be hidebound by contracts. Just do things because they're the right thing to do if, for no other reason, than it'll make you feel better about yourself and your future, and you'll be able to tell your kids that you've done it. To get involved in things, and particularly with yourself and Ofwat, because the worst you could say, I guess, is, "No, we can't do that," but if you don't, you can't do it.

Jo: Try me.

David: Does that about summarise things?

Jo: Sounds great, David. Thank you for listening and thank you for asking this wonderful question.

David: Dr Jo Jolly, Director of Environment and Innovation at Ofwat, thanks for joining me on Behind the Built Environment podcast. Thank you.

Jo: Thanks, David.

David Frise: Hello, I'm David Frise, Chief Executive of BESA, and welcome to Behind the Built Environment, the podcast where I delve into the major issues facing our industry through in-depth conversations with key industry leaders. Join us as we explore the trends, challenges and innovations shaping the future of the built environment. And today our guest is Suzannah Nichol. Welcome, Suzannah. Thank you very much, David. Suzannah is the Chief Executive of Build UK, the leading representative body for the UK construction industry. Her passion for construction began with a site visit during work experience, leading her to study construction management and begin her career as a site engineer. She later qualified in health and safety and went on to lead the National Specialist Contractors Council. In 2015, Suzannah spearheaded the creation of Build UK by merging key organisations, uniting the industry under one voice. Under her leadership, Build UK has driven major industry improvements, including better payment practices through benchmarking and the introduction of the common assessment standard. Suzannah is a respected voice in government, the media and across industry bodies. She holds an MBE 2005 and an OBE 2024 for services to construction. Her leadership roles include serving on the Construction Leadership Council, Building Advisory Committee, Women's Business Council and others. A strong advocate for flexible working, she also one of Timewise's first power part-timers. Again, welcome, Suzannah. Thank you. We like to kick off with quickfire. Yes, no, it's more difficult than it looks on this one. So, here we go. Will the building safety regime be delivered in the next 10 years? Should say fully delivered. No. Will we ever not have a skills crisis in construction? Yes, but not a crisis. Can the industry help deliver the government's targets for growth and house building? Yes. Are buildings safer now than they were before the Grenfell disaster? Yes. Has collaboration across the sector improved since the formation of Build UK? Yes. And finally, one for our members. Will cash retentions ever be abolished? I'd like to say yes. So would I, and I know our members would. First of all, how did you come into the industry? What was it that drew you into construction and what held you in construction, shall we say?

Suzannah Nichol: Back in the days when at school you did work experience, I did two weeks work experience, a week in a children's nursery. I thought I might like to work with children. One week in a nursery put me off that. I went out on a week's work experience with a friend's dad who was an estate agent. And one of the days he took me out on a house building site. I presume he was responsible for selling the houses. And as soon as I walked on site, the noise, the smells, the look, I just knew there and then I wanted to be part of that. So I went home to my parents, my father's a police officer, my mother's a nurse and said, I want to get into construction. And this is before the days of Google and the internet. But we found a company willing to sponsor me and I toddled off to Liverpool University to do a construction management degree. And I've loved it ever since.

David Frise: Yeah, I wonder how many people have had that experience for the first time they went on a building site and they loved it. But that's great to hear. And no regrets since?

Suzannah Nichol: Not at all. I was out yesterday on HS2 Old Oak Common project, part of our Open Doors initiative. And I had that same feeling. And this is now 30 something years later. And I just love the buzz, love seeing what we do, seeing what we contribute to society. I pretty much enjoy every day I go to work. I think I'm really lucky in that. But there's not a day that I've regretted joining the construction industry.

David Frise: That's great to hear. So Build UK reaches a significant milestone this year, which is 10 years. Can you tell us why was it created? And what would you say are the organisation's most important achievements?

Suzannah Nichol: It was created, if I look back about 17, 18 years ago, when I was sitting around tables, particularly in front of government with an ever changing array of ministers, and the industry would sit down with its various voices and bodies and essentially argue amongst itself in front of the minister of the day, which gave them complete licence for them to make the decision. And I think the industry should have, should be ones making the decision. A lot of what we do, a lot of what we could change is within our gift. So I sat there thinking about how we could do this differently. The first step was to start organising the industry before it went to the meetings, work out what we agreed on, and talk about that, not the things that we disagreed on. And then there came the opportunity to bring together initially that what we call the core contracting supply chain, the major contractors, the tier one contractors and the specialist supply chain, which I represented. And there was an opportunity with two people. So James Waits, who was chair of the tier one contractors group, and Kevin Louch, who was chair of the specialists, to do something different, to actually say, shall we bring everybody together? We then have the difficult conversations round the same table, but we work out what we agree on. And actually, most businesses at their core, we agree on the same things. We want financially resilient, good, strong, safe businesses that employ people, that deliver great buildings, and we grow as a sector together. And I often say we fight over the slice of the pie, whereas if we grow that pie, there's much more for everybody. So that's what led to the creation of Build UK. And to answer the second part of that question, I think people thought it would be more difficult than it was. Right at the beginning, there were a few voices who said, you'll never do it. You'll never come together. Within nine months, both parties had said, yes, let's give it a go. It's almost what could possibly, you know, what's the worst that could happen? Having everybody around the table immediately changed the conversation, and it was really refreshing. Yeah, there's difficult conversations. You mentioned retentions earlier. We still haven't resolved that. But we've made steps forward in it. We've fundamentally changed the conversation on payment, and we've improved payment metrics. So you ask, what have we done in that time? We've improved payment metrics. Our members, when we started benchmarking them, and transparency is key, when you start to put things in a league table, it starts to drive different behaviours. Our members have improved their average payment terms from 45 days. Now it sits at 29. That's big. That's in the last seven years. We've introduced the common assessment standard. So we've started to unravel the very complicated landscape of pre-qualification. I think there were 21 schemes. You now can get the common assessment standard from recognised assessment bodies. And it teed the industry up for when the Building Safety Act came in. We didn't have to start for a new scheme looking at organisational capability. We said, you know what, we've got one of those, and a lot of people are signed up to it. We added in the building safety changes, the questions, so we hit the ground running, which is a first for the industry to be lined up, ready to go, and everybody saying, yes, we can do this.

David Frise: That's one of the big things, I think, for Visa members around that common assessment standard. How do you see that operating in the future? Many of our members have multiple accreditations. Is that how you see it continuing, or is there a better way?

Suzannah Nichol: Absolutely not. The objective is you should have one, you should have the common assessment standard, and that will be recognised by clients, contractors. Everything in construction is a long process. We're a huge industry. We all want the same objective, or most people, but we often try and get there in the most complicated way. I often say in construction, why have one piece of paper when you can have 10? So what we've done so far is we now have government recognises the common assessment standard. So the public sector is encouraged and advised to use the common assessment standard, and we're seeing that. We've just updated it for the new Procurement Act. Almost all of our contractor members now require the common assessment standard. The challenge comes in trickling that down through every division and every department in every contractor. So they ask for the common assessment standard. And stopping that construction not invented here syndrome. So we like the common assessment standard, but we want a few of our own questions. And it's saying, stop, bring the questions to the table. If they're valid and everybody wants them, we'll consider incorporating them. Stop adding layers just for the sake of it, and having those open conversations. So I see in the future that will be the requirement, the common assessment standard. It's in some of the frameworks now. It's in the government's biggest framework. It's been used by MHCLG for the cladding remediation project. So we're getting there. There's a huge role for the supply chain here as well. When they're asked for something, and they've got the common assessment standard, they should turn around and say, we've got the common assessment standard. We've jumped through that. We've achieved that. And then they should come and tell you, and they can come and tell me. And we can go and have that conversation saying, why are you asking for this? And often it's not really understood why. And I think we can do a huge amount in saying, you don't need to do that. This is the industry accepted standard. Now let's focus on something else that's really going to make a difference.

David Frise: That's one area where the industry duplicates a lot, and therefore that costs a lot of money and adds no real value. Productivity is one of the key areas you've focused on. Where do you see the kind of easy wins? Well, I think you've discussed there are no easy wins in construction, but where's the point of attack on productivity? Because we have lamentable productivity, not just in construction, but in the UK generally.

Suzannah Nichol: We have huge waste in construction. When people talk about productivity, the challenge is everybody sees it as slightly different, different reasons for it, different definition of it. Duplication is one way, and we find that all the time, where we'll issue a simple industry standard that the majority sign up to. And everybody says, we'll just add our own little bit to it. So we have to try and stop that mentality. And demonstrating how wasteful it is, I'd much rather, for instance, on pre-qualification or demonstrating organisational capability, people said, what will really make the difference on site? What will make us safer? What will improve the standard? It's not filling out another piece of paper. It's paying for whether you bring back your clock of works out on site. It's spending more time upfront in the design of your project. So you know it complies with building regulations. You've considered all the issues. You've modelled it. You've used BIM. Every time we do something that's waste, maybe we should actually start to say that, but this is incredibly wasteful. How can we do it differently? So that common terminology. But you see it everywhere. From the lack of use of technology on site, we could be so much more productive with some real simple adoptions of technology. Online forms rather than paper forms, up to some massive big decisions, such as sorting out design problems before we get on site. And then we're reworking out on site.

[00:11:35] David: Yeah, we often start projects too soon. And therefore, we're into building design rather than design and build. There's an ongoing conversation around the need for the industry to develop a new culture, and not least because of its response to the Building Safety Act. But what practical steps do we need to take to turn that into a reality, do you think?

Suzannah Nichol: Changing a culture is a really difficult thing to do. Again, everybody thinks you mean something different. And I often talk about if you want to change something, which is turning a big cog, you need to turn lots of smaller cogs to get that big cog turning. And the industry is reasonably compliant. It likes structure. It likes rules as a principle. So looking at some of those smaller things that make people's lives better, take competence. It's really difficult to turn the big wheel on making sure everybody's competent if we don't have the standards in place. If we don't, not everybody's checking cards when they go on site. Not everybody is clear on what qualification is good looks like. And when you have people saying, I've got 40 years experience in the industry, I'm fine. So addressing each of those little cogs and making a difference there actually starts to turn what some people would call the culture cog, the culture wheel. So by doing some of the smaller things, the pieces of the jigsaw, you will change the culture. You don't change a culture by saying we need to change a culture.

David Frise: Now, indeed, and there is a kind of a cognitive dissonance in the industry, the difference between what people say they do and what they actually do. And I guess the reporting piece around the payment leak tables shows what actually happens rather than what they say happens. I've just come back from the US. There was a huge, to the MCA conference, which is our equivalent in the US, a lot of talk about AI and how they are developing AI tools for back office function, but also in sort of engineering functions. Do you see the use of AI being used in construction a great deal more, and particularly around maybe that reporting, the difference between what you say you do and what actually happens?

Suzannah Nichol: The potential is huge,not just in reporting and some of the more ways we think of, the easy ways. Out on site yesterday, they're talking about using drones to deliver. They're talking about where you could have automatic paint sprayers. So you will no longer be looking for people to paint the wall. You'll be looking for people to operate the equipment that paints the wall. We are behind the curve in that. There's a whole range of reasons. Construction's high risk to change things. Change is so big, you'll only find out it's not working when you're into what could be a two, three, four, five-year project. So it's quite massive to actually take the step and say, we're going to do something different untested on this project. That's part of our challenge, but it's also a huge opportunity. So I absolutely believe that going forward, we will look back, a bit like we've all got a phone. I no longer carry an A to Z. I no longer carry a credit card. I don't even carry money these days. If I can't pay on my watch, I'm not buying. That's technology. That's AI that has crept into our lives that I didn't even know I need, but I now wouldn't be without. And I truly believe we've got that huge potential in construction. The fact that we require lots of small firms to make that investment is our big, big challenge. We need to say what would make the biggest difference and everybody lean in and say, do you know what, we're going to do that first.

David Frise: Yeah. They had an interesting slogan saying AI will not put you out of business, but a company using AI might.

Suzannah Nichol: Absolutely. First of all, we have got a skill shortage. We've got a labour shortage. So worrying about it, taking jobs absolutely should not be top of our list. I think the skills will change and I suspect that will play into the next generation as well, who are much more used to running their life on a digital platform. So inviting them into operate equipment that paints walls is probably a much more attractive proposition than inviting them in to paint the walls. So again, huge opportunity that will also then back to reduce our waste, drive our productivity. I'm back to, it's quite exciting working in this sector.

David Frise: We touched earlier about the skills crisis, shall we say, and you've talked already about open doors and going out to the HS2 site yesterday. Can you tell us a bit about HS2, sorry, open doors rather than HS2, but open doors, what it's about and how that's going to help us with the skills shortages?

Suzannah Nichol: Open doors is an initiative run by Build UK where our members and others open up their, not just construction sites, that's the main, but we open up offices, workplaces, we've got some virtual events, we've got plant yards, depots, anything and everything where we open them up across a week and young people, particularly schools, colleges, universities we target, but also anybody in the community can come on a live construction workplace and see what we get up to. We have so many jobs in construction that we find it difficult to explain in a 30 minute careers talk, it's really difficult. So bringing those young people outside and showing them what goes on means they start to ask the questions, they start to see the range of opportunities. And we know from our research that 88% of our visitors to an open doors site would then consider a career in construction. So it's that first step from their journey from education into employment, which is really difficult in this country. Even yesterday I had a group of college students join me and they didn't really know what they were up to. By the time they'd heard from people on HS2, they'd seen the project, they were buzzing. And the kind of things I was saying, well have you had any work experience? Well no. Right, you need to get out and get some work experience. But they were much more excited going back to their college course because they could see what they could be. The next step for us is when they leave is saying, and this is your next step. And we now have to build that because it's really difficult to get a job in construction. We've got a skills crisis but we make it really difficult for people to join us. And trust me, people want to join us. We do not have a recruitment problem, we do not have an attraction problem. We've got a lot of young people on courses, they just can't make that step from that course into the industry. And Open Doors is part of that. And it gets the employers engaged as well. Employers are seeing that potential and we often find they find their next apprentice on those Open Doors visits because somebody comes up and says, I'd love to work here. And they say, happy days. Our apprenticeship programme starts in a few weeks, here's the application form. So it really connects the industry with people we want to join the industry.

Suzannah Nichol: The average age, I think, is in the 50s in the industry. And we've talked a bit about culture change and how the industry is developing. Is it a generational change that's going to be required before we really start to see a, shall we say, purely digital, modern industry in the form that we all want to see?